Electronics Manufacturing Services

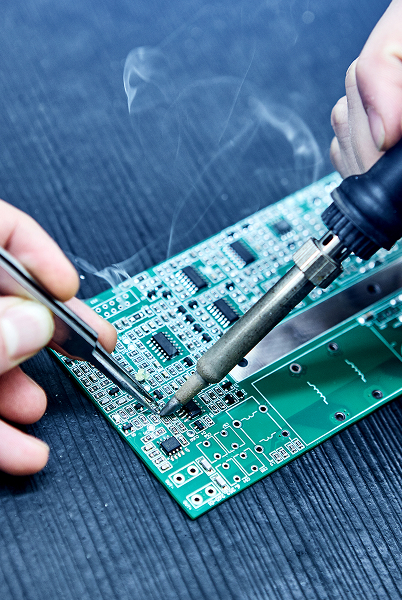

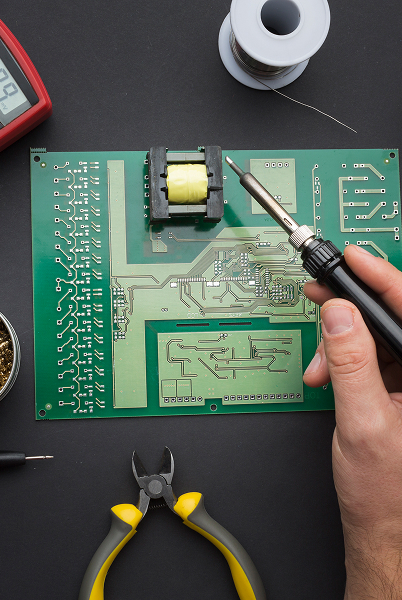

PCB Assembly (PCBA) Services

We offer high-precision PCB Assembly (PCBA) services catering to a variety of customer needs, from high-mix, low-volume production (customized small batches) to low-mix, high-volume production (large-scale manufacturing).

Box Build & System Integration

We go beyond PCB assembly by offering complete box build assembly, integrating multiple components into a finished, ready-to-use product.

End-to-End Turnkey Solutions

We offer complete product development and manufacturing solutions, supporting customers from concept to full-scale production.

Why choose CEM Electromech?

CEM Electromech delivers high-quality, scalable, and cost-effective Electronics Manufacturing Services (EMS) with end-to-end solutions from PCB assembly to full system integration. Our state-of-the-art SMT lines, expertise in complex multilayer PCBs, and specialized processes ensure superior precision and reliability. We offer rapid prototyping, NPI support, and turnkey manufacturing, enabling faster time-to-market. With strong supply chain management, localization support, and comprehensive testing capabilities, we provide seamless, high-performance manufacturing solutions tailored to diverse industry needs.